Humanoid Robotics Kit: From Concept to Application

At Promwad, we believe that internal R&D is not just a playground for experimentation — it's a strategic investment to accelerate engineering for our clients.

This article introduces our humanoid robotics kit, developed in-house to fast-track the creation of service robots. By building a complete prototype platform — from mechanical layout to software stack — we help our partners shorten time-to-market and simplify robotics development in sectors such as hospitality, warehousing, and healthcare.

Mechanical Architecture and Kinematics

Most tools and objects in human environments — door handles, switches, stairs, benches — are built for the average adult. For a humanoid robot to operate naturally in such spaces, it must replicate the human range of motion and workspace while staying mechanically simple for manufacturing and maintenance.

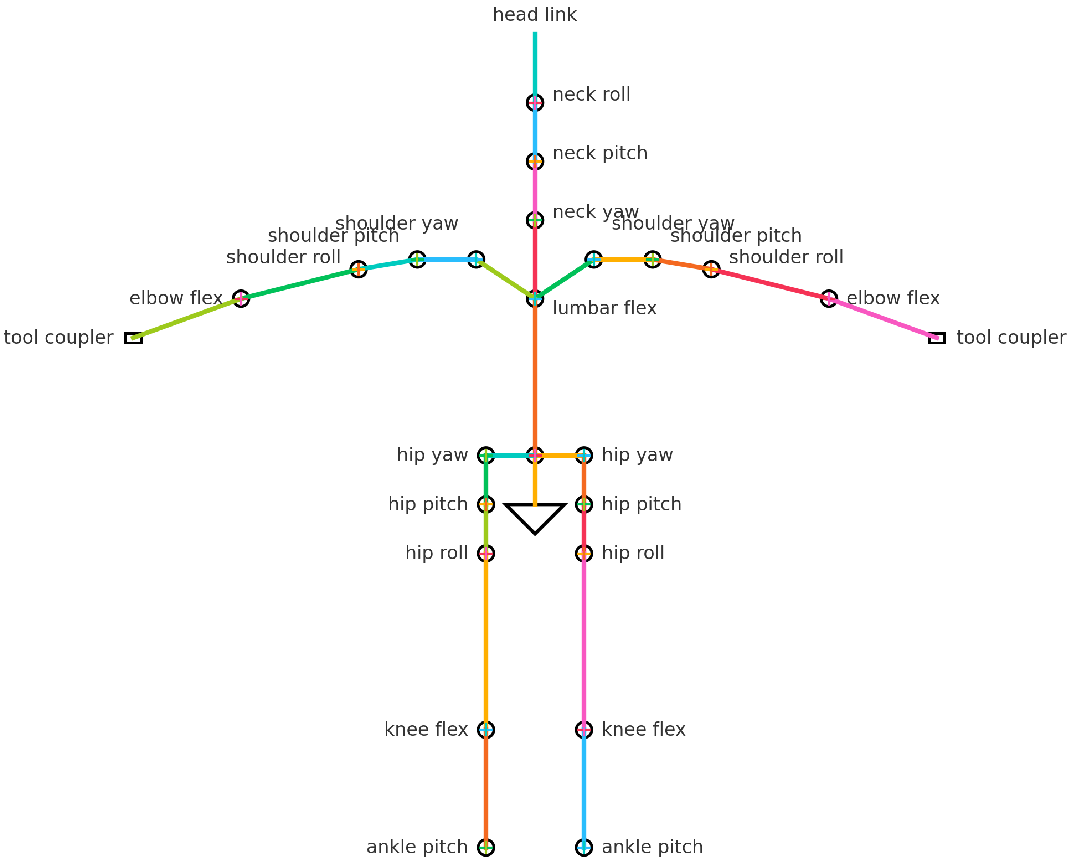

We adopted an anthropomorphic design with 22 controllable degrees of freedom:

- A floating pelvic base that acts as the global reference frame

- Symmetric 4-DOF arms for bimanual manipulation

- Symmetric 5-DOF legs for dynamic locomotion

- A 3-DOF head for perception

- A 1-DOF lumbar joint for center-of-mass shift during lifting and climbing

This configuration minimises redundancy and weight while covering the angular ranges required for industrial and domestic tasks.

Kinematic structure of the humanoid robot: a simplified joint diagram showing 26 controllable degrees of freedom, including symmetric arms and legs, a 3-DOF head, and a lumbar joint — enabling full-body mobility tailored to human-centric environments.

Inverse dynamics analysis (15 kg payload, 1.5 m/s walking) revealed peak torques up to 210 N·m at the hips and knees, with joint speeds of 10–13 rad/s. After surveying available torque-dense actuators, we selected the MyActuator X12-320 for all powered joints:

- Peak / continuous torque: 320 / 100 N·m

- No-load speed: 125 rpm (≈13 rad/s) at 48 V

- Gear ratio: 20:1, zero backlash

- Integrated 16-bit absolute encoder and torque sensor

- EtherCAT interface

X12‑320 servo actuator by MyActuator: High-torque servo used in all robot joints, offering 320 N·m peak torque, integrated sensors, and EtherCAT interface — enabling unified drive architecture with minimal wiring and maximum mechanical efficiency. Image credit: myactuator.com

Using a single actuator type reduced the BOM, streamlined thermal management, and simplified spare parts logistics. In joints like shoulders, hips, and neck, we stacked three X12-240 units together. Other joints — elbows, knees, ankles, and lumbar — are driven by single actuators. Hollow shafts route the 48V DC and Ethernet lines internally, eliminating external cable drag. The actuator housings are bolted directly into aluminum-titanium link shells, which also serve as heat sinks. Finite element analysis confirmed safe winding temperatures under 65°C at 40% duty cycle.

With this architecture, the robot can:

- Lift 25 kg from floor to waist height with 30% torque reserve

- Walk at 5 km/h

- Absorb lateral pushes up to 250 N without knee saturation

- Maintain end-effector accuracy within ±1 mm RMS while carrying 10 kg

These results validate our kinematic layout and actuator choice for robust, human-scale manipulation and mobility.

End-Effector Design

Tool Changer

To enable automatic switching between grippers, we integrated the Zimmer FWR (“Manu-Matic”) quick-changer.

FWR is a fully mechanical system. When the wrist plate slides into the parking station, the spring-loaded latch auto-releases and locks again on withdrawal — no pneumatics or 24V actuator required. This allows seamless switching between the anthropomorphic hand and a three-finger gripper while maintaining a clean EtherCAT + DC-only architecture.

Zimmer FWR quick-change system: Mechanical tool changer enabling fully autonomous end-effector swaps without pneumatics or external drives — ensuring fast, fail-safe transitions between tools while keeping the wrist lightweight and EtherCAT-only. Image credit: zimmer-group.com

For our ≤25 kg payload, we use the compact FWR63 model, which provides 30 kg margin. Standard WER 1500 media modules mounted on the changer route:

- EtherCAT or GigE via RJ-45 / M12 D-coded ports

- DC power (25 A max) through 4- to 12-pin blocks

- Optional pneumatics (up to 4 lines)

An inductive sensor confirms docking. The FWR ensures:

- Fully autonomous tool exchange

- Unified comms and power routing

- Fail-safe mechanical latching even under power loss

Three-Finger Gripper

This gripper handles bulky or irregular objects that are challenging for anthropomorphic hands. It includes two motors — one for rotation, one for grip — and strain gauges to measure force and stability.

Elmo Gold Solo Guitar 25/60 A or Ingenia ServoCore drivers are stacked inside the base, exposing a single EtherCAT node to the wrist harness.

Elmo Gold Solo Guitar servo drive: Compact EtherCAT-compatible motor controller used in the base of the three-finger gripper — enabling precise motion control in a space-constrained, lightweight design. Image credit: elmomc.com

Each finger uses the Fin Ray effect — flexible ribbed fins that conform to the object shape, spreading load and boosting grip friction. This passive adaptation increases holding force by 30–40% over rigid jaws.

Three-finger Fin Ray gripper: Soft-adaptive end-effector using ribbed, flexible fingers that conform to various shapes — achieving 30–40% higher holding force than rigid jaws while maintaining a lightweight, cable-free structure. Image credit: sheen.co.za

Anthropomorphic Gripper

We equipped the robot with the SCHUNK SVH hand — a five-finger device that mimics a full-scale human hand. It offers 20 DOF powered by 9 embedded motors, weighs only 1.3 kg, and runs on 24 V DC.

All power and RS-485 comms are integrated at the wrist. Mounting to the Zimmer FWR plate requires only one power line and one twisted-pair signal. The rest is routed internally.

The SVH enables:

- Pinch, hook, and power grasps

- Fine control of small parts

- Seamless ROS 2 integration for fast setup

SCHUNK SVH five-finger anthropomorphic hand: Full-scale robotic hand with 20 degrees of freedom and nine integrated motors — enabling dexterous, human-like manipulation for complex grasping tasks in service robotics. Image credit: schunk.com

Hardware Platform

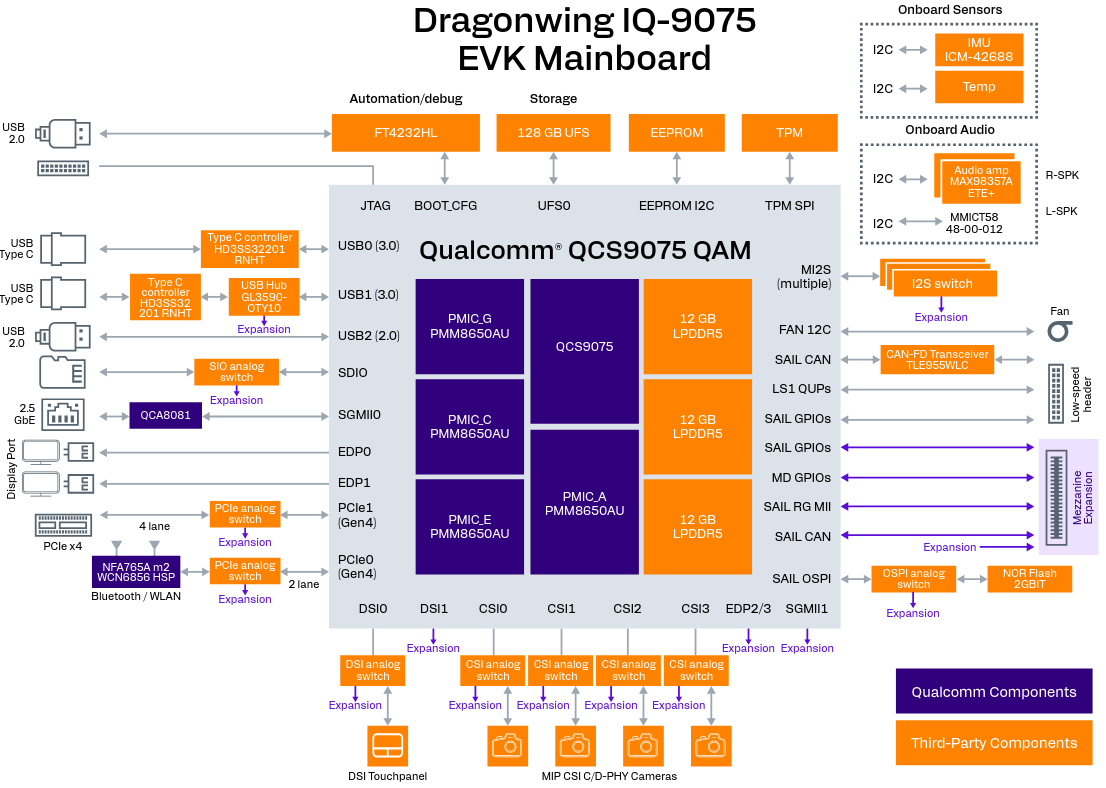

The Qualcomm Dragonwing™ IQ9 platform delivers the performance and efficiency needed for robotics. With a hybrid architecture across CPU, GPU, and a 100 TOPS NPU, it handles complex AI tasks like 4K video processing, real-time navigation, and machine perception.

Block diagram of the Qualcomm Dragonwing IQ‑9075 EVK: High-performance embedded computing platform featuring the QCS9075 SoC, 12 GB LPDDR5 memory, and multiple high-speed I/O interfaces — ideal for edge AI and robotics applications. Image credit: qualcomm.com

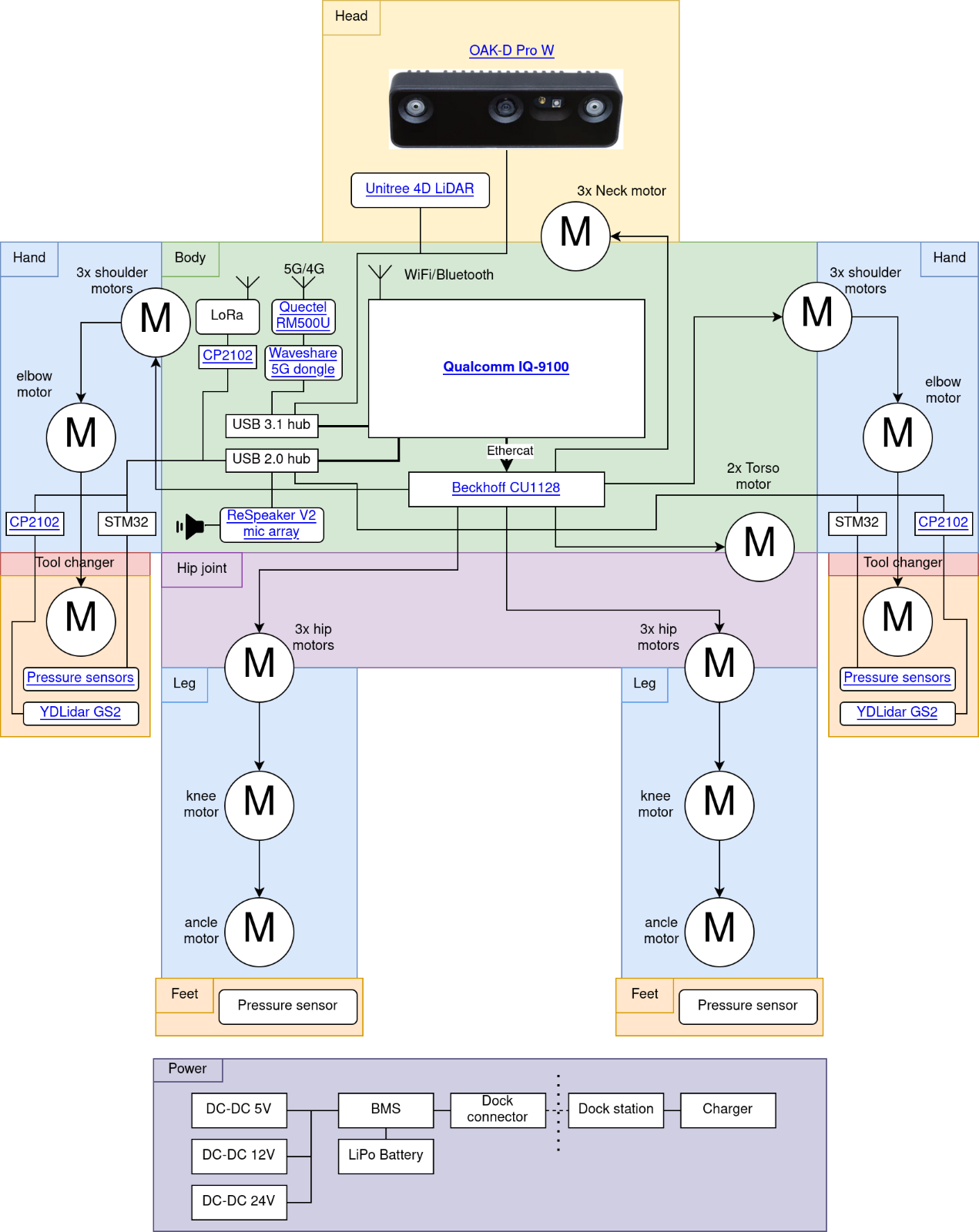

We use a modified IQ-9100 version with the same functionality as the IQ-9075, plus added security features — TrustZone, DRM, crypto accelerators. The IQ-9100 connects to a Beckhoff CU1128 via its Ethernet port, acting as the EtherCAT master. This layout ensures distributed yet synchronised motor control. Fault tolerance is achieved by isolating motor groups.

Hardware architecture block diagram: The central computing unit of the system is the Qualcomm Dragonwing™ IQ-9100 Dev Kit, which integrates all key components for control, perception, and communication in the humanoid robot.

Connectivity & Sensors

The robot supports:

- Wi-Fi for basic indoor use

- 5G/4G via RM500U modem (M.2 PCIe)

- Bluetooth for peripherals

- LoRa for low-bandwidth fallback communication

Sensor suite includes:

- Luxonis OAK-D Pro W: 4K camera with depth + IMU for visual-inertial odometry

- Unitree 4D LiDAR: blind spot coverage

- YDLidar GS2: mounted on gripper to detect object position and size

- ReSpeaker V2: microphone array for voice source localisation and speech isolation

Power Management

The robot is powered by a 1 kWh 10S battery with UART BMS. Runtime: 1.5 hours at full load, up to 3 hours in real use. Charging time: 4.2 hours.

Software Stack: Isaac Sim + GR00T

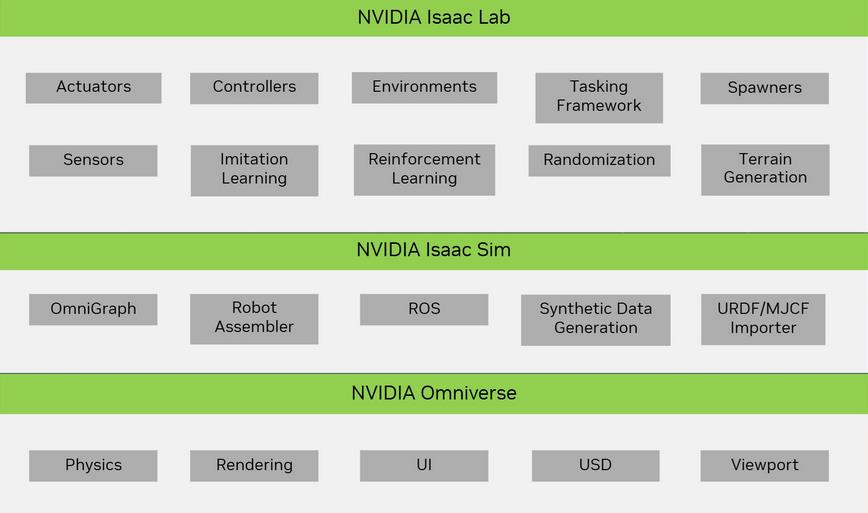

We chose NVIDIA Isaac Lab and GR00T for simulation, training, and real-time control.

Isaac Lab in Omniverse Digital Twin: Simulation of large-scale humanoid robot behavior in complex environments using NVIDIA Isaac Lab — enabling robust training, validation, and motion planning before real-world deployment. Image credit: nvidia.com

Isaac Sim allows full-physics simulations of the robot, including drive tuning and coordination testing before deploying to real hardware. It supports AI integration and reduces risk during development.

NVIDIA Isaac software stack overview: Layered architecture combining Isaac Lab, Isaac Sim, and Omniverse — enabling end-to-end development of robotic systems through simulation, training, synthetic data, and real-time visualisation. Image credit: nvidia.com

GR00T includes:

- Teleop: telepresence for demo capture

- Mimic: synthetic motion generation

- Dexterity: end-to-end grasping skills

- Mobility: adapts robot to unknown environments

- Control: unified body control stack

- Perception: VLM + LLM + memory for cognitive flexibility

Its flagship model, GR00T N1 B2 (2.19B params), supports multimodal interaction. The IQ-9100’s 100 TOPS edge AI performance enables real-time inference without cloud dependence. A 512-token forward pass is estimated under 100 ms — fast enough for real-time voice and motion applications.

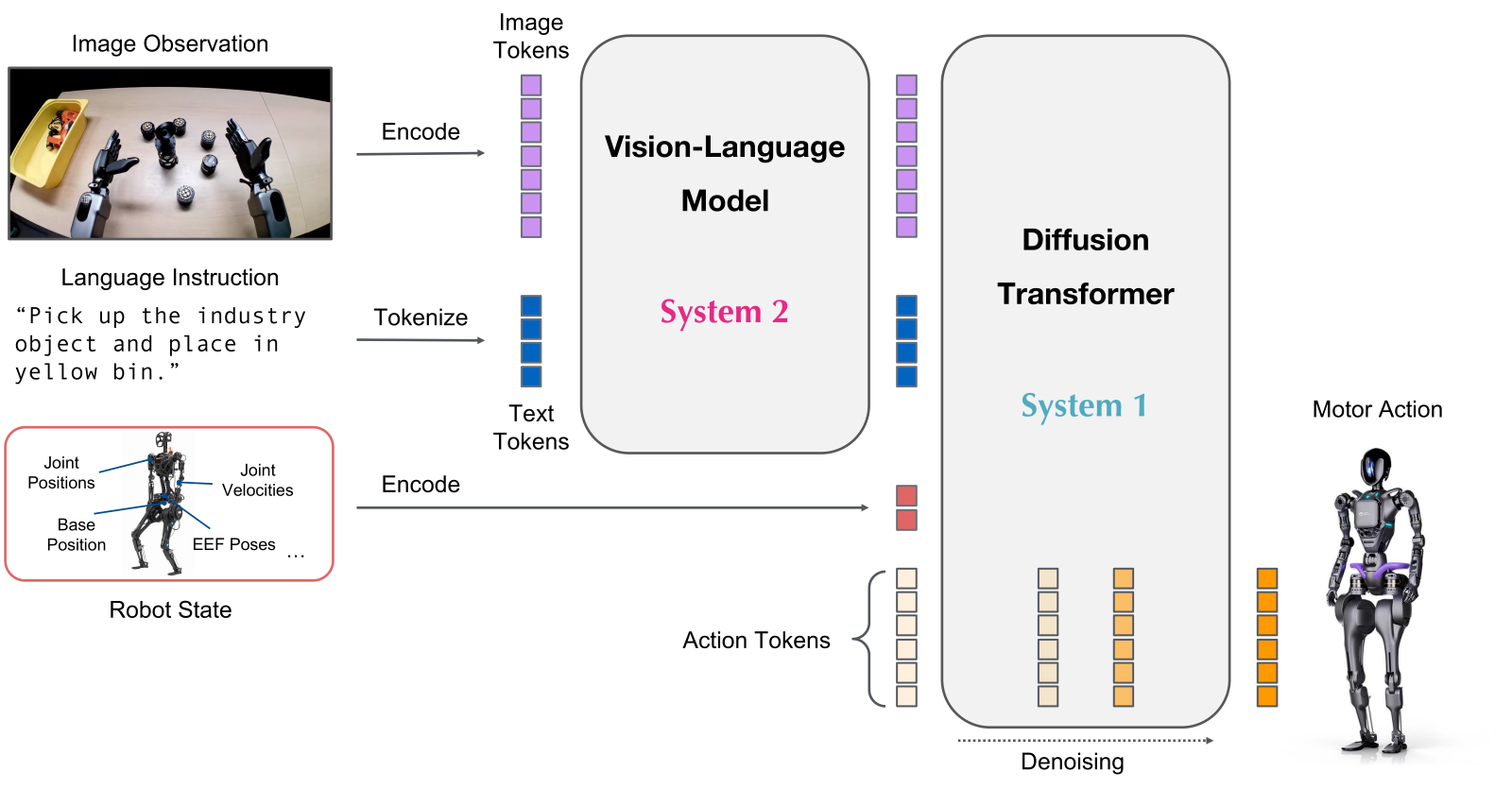

GR00T network architecture: Multimodal model pipeline combining vision-language understanding and action generation through a diffusion transformer — enabling humanoid robots to interpret instructions and perform complex motor tasks. Image source: Gr00t GitHub

Business Value

This robotics kit enables clients to enter the service robotics market faster. The off-the-shelf platform shortens development cycles and allows customisations across verticals like hospitality, healthcare, and logistics.

With built-in navigation, object interaction, and human awareness, our platform is ideal for autonomous service tasks in dynamic environments.

If you're developing a robotics solution and want to accelerate your time-to-market, get in touch with Promwad to explore collaboration opportunities.

Our Case Studies in Robotics