Access control device design

Client

The leading smart card and RFID tag manufacturer in Eastern Europe.

Challenge

Our client commissioned Promwad for industrial design services for a wall-mounted smart card reader for physical access control with the required width, height, and minimum possible depth.

The device is placed on the wall directly at the entrance terminal to allow personnel access by individual access cards, both indoors and outdoors.

After several years of manufacturing in the original size, the client decided to make it smaller and adapt the enclosure for door trim.

Solution

Promwad industrial and mechanical designers solved the following essential tasks:

- Stylish industrial enclosure design with the basic requirement of enclosure depth minimization.

- Compliance with IP67 protection requirements. ▪ Enclosure illumination with the internal light-emitting device.

- Easy assembly and maintenance of the device.

-

Enclosure design

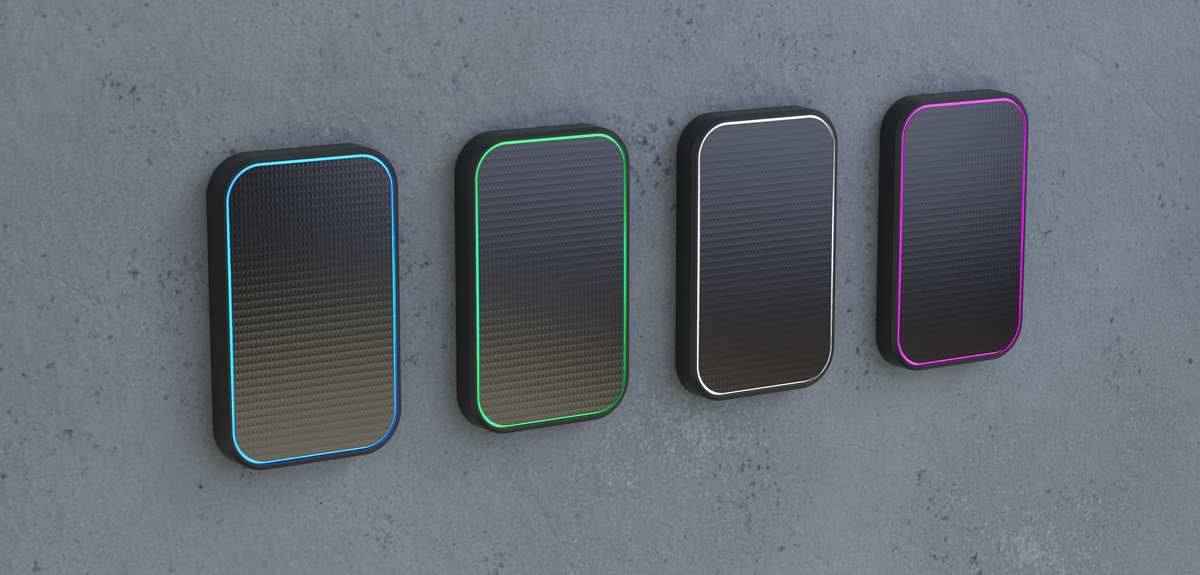

The enclosure design presents its manufacturing in the colors of the customer's company brand book, customizable front panel, and uniform glow on the front panel and the edge along the contour.

-

Mechanical design

Before the industrial design project stage, we've analyzed the client's existing products, market analogs, and trends in the similar protected enclosures implementation.

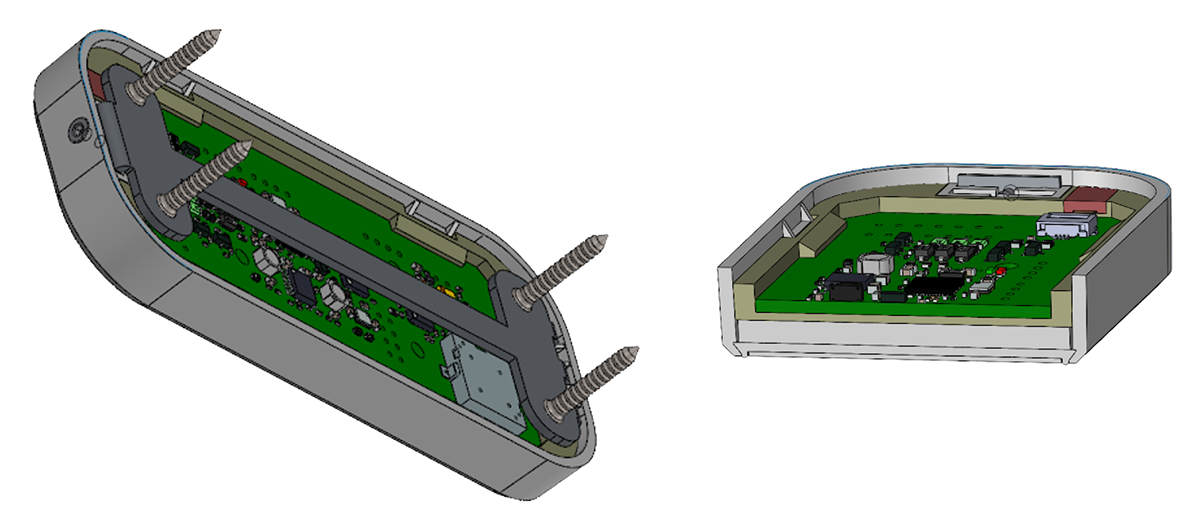

We decided to use two-component molding with inset transparent polycarbonate glass of the required transparency to eliminate the use of the glass bonding operation.

We've studied and tested various options for using both LEDs and light guides to achieve uniform illumination. Finally, we decided to use a light guide with the exact contour of polymethylmethacrylate (PMMA) with a thickness of 2.8 mm using a scattering film screen and glued LED strip with a set of 5 oriented LEDs emitting light in two directions.

![]()

Our mechanical designer installed the PCB in a silicone enclosure. Then they filled it with a compound after installation. That provided the assembly facilitation and hermeticity insurance. Despite the increased assembly time at the client's site, this contributes to the complete sealing of the components.

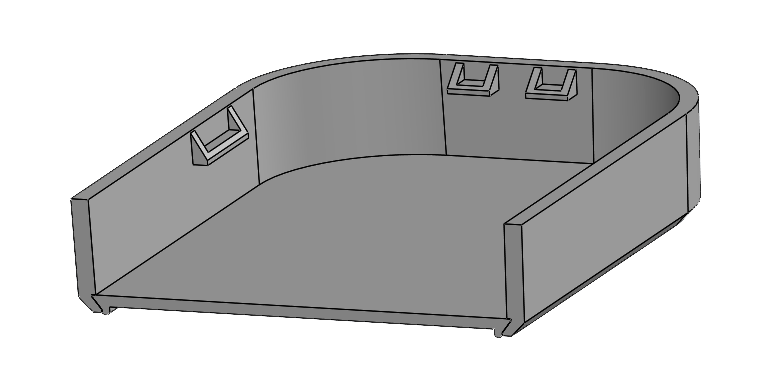

We've designed a bracket with the non-dropout screw as a component to mount the device on a wall.

During the manufacturing of one batch, the client requested a one-piece translucent white enclosure.

-

Production launch

Here is an overview of the manufacturing preparation before the launch.

We've chosen the overmolding method of injection molding for enclosure manufacturing.

For the first mold, we cast the matte-colored glass with the selected transparency (transparent PC). This glass is then inserted into the enclosure mold, and the second ABS component is poured.

The fiber is made by the following method: first, the contour of a sheet of transparent polycarbonate 2.8 mm thick is cut out by laser, then a shaped groove is milled to accommodate a flexible board with 5 RGB LEDs.

The flexible board is attached to the light guide with an adhesive layer.

Troughs for laying the main board and blind stubs of the optical fibers are made of two-component polyurethane resin by pouring it in a silicone mold.

The bracket for mounting the device on the wall is made of steel, cutting from a metal sheet with a thickness of 2.0 mm with a specially made stamp.

Then threads are cut to attach the enclosure, and holes are drilled for self-tapping screws, which fasten the bracket to the wall. Finally, the finished bracket is powder-coated to protect the metal from external influences.A special non-dropped screw with M2 thread provides easy assembly and disassembly of the enclosure during installation and repair work.

Result

The designed access control device combines ease of assembly and installation with reliable and fast wall mounting. In addition, we ensured the required uniform glow of the front panel.

We considered the minimum number of enclosure parts, which had a positive impact on the manufacturing costs. Besides, we've selected the optimal surface roughness for the best tactile and visual effects.

Our client received a stylish enclosure with full RGB backlighting and the ability to change the design and texture at their customers' request.