What's New in ASPICE 4.0? Key Updates and Improvements

Automotive SPICE 4.0 (ASPICE) is the latest version of the internationally recognised process assessment model and assessment framework for the development of automotive software and systems. ASPICE provides a standardised approach to evaluate and improve the software engineering processes of automotive suppliers.

Promwad delivers customised services to assist clients in implementing projects that comply with the ASPICE CL2 standard. This strategy helps us to address the most important standards of automotive market leaders: high-quality and safe embedded transportation systems.

Why does your business need ASPICE 4.0?

ASPICE 4.0 enhances our technological capabilities by integrating the best engineering practices to produce higher-quality, more reliable, and safer products. Our clients can trust that their projects are developed according to the highest industry standards for automotive software and systems.

Additionally, ASPICE 4.0 emphasises continuous improvement and a more structured approach to software development. Every phase of the project is meticulously planned, monitored, and optimized, resulting in efficient execution and faster time to market.

By aligning our processes with the ASPICE 4.0 standard, we ensure that our development work meets the rigorous requirements of leading automotive companies. This boosts the credibility of our clients' products and creates opportunities for collaboration and partnerships with top players in the industry.

Key features of ASPICE 4.0

ASPICE 4.0 has introduced a range of updates to improve quality and efficiency. These new features enhance process capability, integrate advanced engineering practices, and ensure higher levels of safety and compliance.

- Alignment with ISO/IEC 33002:2015 for performing process assessments, ensuring consistency and reliability.

- Incorporation of agile practices that responds to the increasing adoption of agile in the automotive domain makes the development processes flexible and iterative.

- Expanded сoverage of systems engineering processes, especially requirements management, design, implementation, testing, and maintenance.

- Improved consistency and clarity: ASPICE 4.0 facilitates more reliable and repeatable assessments, which are well-defined and easy to follow.

- The framework enables benchmarking and comparing process capabilities across different suppliers, helping automotive OEMs evaluate and select suppliers based on their process maturity and capability.

- By adopting standardised processes ASPICE 4.0, automotive OEMs can reduce the risk of project delays and cost overruns due to software-related issues.

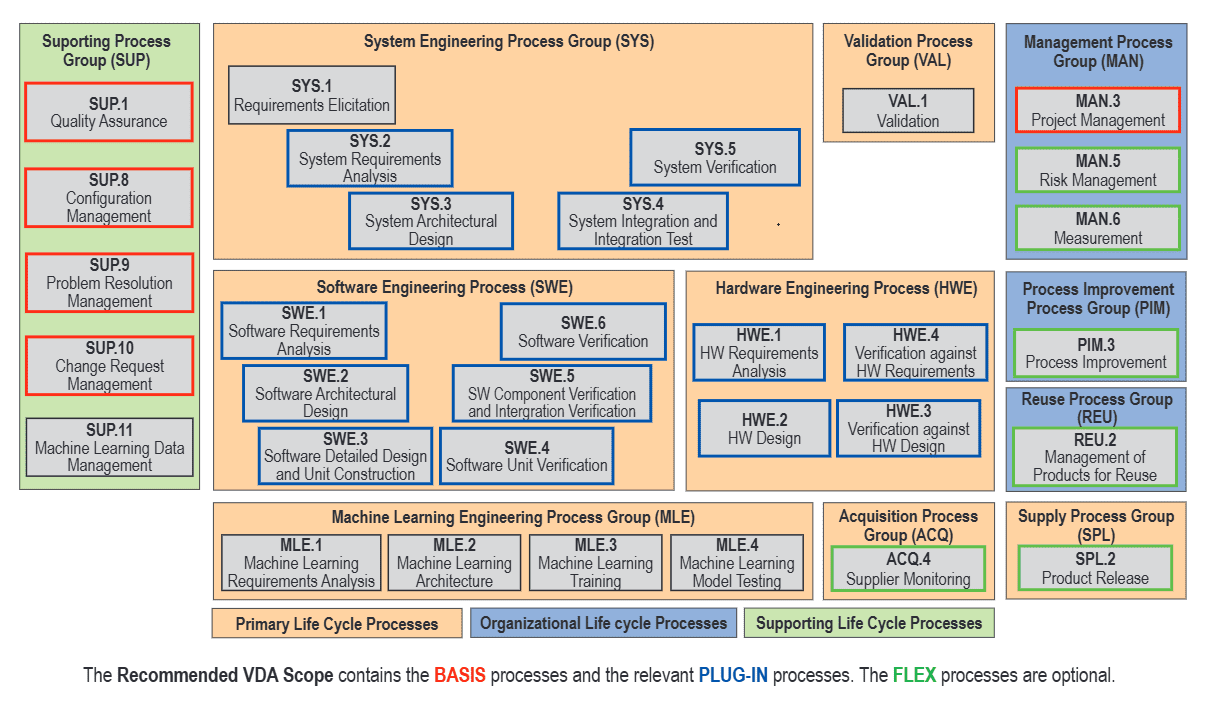

Automotive SPICE 4.0 process reference model overview with 10 new processes. Source: Knüvener Mackert GmbH, Automotive SPICE® Assessment & Consulting

New process areas introduced in ASPICE 4.0

ASPICE 4.0 introduces several new process areas to better address the complexities of modern automotive development:

1. MLE (machine learning engineering). ASPICE 4.0 includes four specific processes (MLE.1 – MLE.4) dedicated to machine learning engineering. These processes focus on developing and integrating AI and data-driven technologies into automotive systems.

2. HWE (hardware engineering). The new version adds processes for hardware development (HWE.1 – HWE.4), which are essential for the comprehensive development of mechatronic systems. This inclusion highlights the critical role that hardware plays with software in vehicles, especially with the rise of electric and autonomous vehicles.

3. VAL (validation process). A new validation process (VAL.1) has been introduced to ensure that the overall system meets its requirements and performs as expected. This process is crucial for verifying that integrated systems function correctly in real-world scenarios.

4. SUP (support process for data management) specifically for data management in machine learning. This process addresses the need for effective data handling throughout the machine learning lifecycle, from collection and storage to processing and analysis.

How does ASPICE 4.0 differ from previous versions

ASPICE 4.0 has some changes compared to its predecessor, ASPICE 3.1, to better address the evolving needs of the automotive industry. Here are the key differences:

Expanded scope to encompass the entire mechatronic development process, integrating process models for hardware engineering and machine learning engineering. This expansion allows for a more comprehensive approach to developing complex, integrated systems, which are increasingly important in modern automotive projects, such as electric and autonomous vehicles.

The Promwad team uses Siemens' Polarion ALM, a powerful tool that centralises information and links various project phases. This tool enables efficient management of the entire lifecycle of applications and embedded systems, from wireless charging to automotive computer vision. This solution allows us to streamline workflows across distributed teams, unify all engineering processes within a single environment, and track requirements.

Revised process landscape. The process landscape has been updated to reflect modern collaboration models and the complexities introduced by digitisation, automation, and AI. This includes the addition of new process areas specifically addressing machine learning (MLE.1 – MLE.4) and hardware development (HWE.1 – HWE.4), as well as a validation process for the overall system (VAL.1) and a support process for data management in machine learning (SUP.11).

ASPICE 4.0 shifts its focus from "Work Products" to "Information Items". This change emphasises the main results of processes as indicators rather than specific documents, promoting a more holistic view of process outcomes and encouraging organisations to prioritise valuable information over mere documentation.

In ASPICE 4.0, strategy documents are now required starting from capability level 2 rather than level 1 as in previous versions. This change elevates the importance of strategic process management and planning, ensuring organisations have a clear direction and framework for executing their processes effectively.

Enhanced training and assessment models. The new version introduces a training model that focuses on varying degrees of knowledge necessary for different roles, including specialised areas like cybersecurity and agile methodologies. Additionally, ASPICE 4.0 aims for maximum repeatability and reproducibility of assessment results to reduce subjectivity and improve evaluation efficiency.

***

With our adoption of ASPICE 4.0, you can be sure that Promwad is following the necessary processes to develop high-quality and reliable software. This system supports continuous improvement, quality assurance and compliance with standards such as ISO 26262.

We have extensive experience in software and hardware development and help create complex products. The company is ISO 9001 certified, ensuring high-quality management systems and processes in all projects.

Promwad works closely with leading chip vendors such as NXP, TI and Qualcomm, which allows us to offer advanced solutions that meet clients' needs. This complex expertise helps us create reliable products that align with the automotive industry's strictest requirements.

Are you eager to improve automotive-related software and systems? Partner with Promwad to ensure your projects meet the highest standards of quality and safety. Contact us today!