ASIL-C High-Accuracy Current Sensor Design

Project in Nutshell: we designed two types of current sensors for our client in the automotive industry, ensuring safety and optimal performance of the pyro trigger system. Our design was powered by Microchip MCU complied with the ISO 26262 standard and ASIL-C.

Client & Challenge

A manufacturer of automotive safety systems approached us to design two types of current sensors for their pyro trigger system: a simple one and a highly responsive current sensor. The primary objective was to create a device that could generate an error signal in the event of excessive current consumption from the battery, triggering the activation of the pyro patron and subsequently disconnecting the battery. The system needed to monitor the squib state, ensure current monitoring within a specific range and keep tabs on the supply voltage.

Solution

1. Interaction with Client

Our collaboration model was based on a Time and Materials (T&M) contract. Under this agreement, three firmware engineers were engaged in the project. Communication included weekly calls to discuss overall progress, while technical teams maintained daily communication to address specific technical aspects.

2. Current Sensor Design

Our team designed and implemented a current sensor that met the safety requirements for the automotive industry. The key features of the device included:

- Current monitoring within the range of +/- 1700A, ensuring the safety and optimal performance of the pyro trigger system.

- Squib state monitoring. The device provided information on whether it was active, inactive, or damaged.

- Supply voltage monitoring to ensure the system's overall health and prevent potential failures.

- Error signal generation in cases of excessive current consumption. Another ECU utilised this signal to activate the pyropatron and initiate the disconnection of the battery enhancing safety measures.

- Communication via pulse width modulation (PWM) signals with a specific filling percentage, facilitating efficient and reliable data transmission.

We implemented sensor firmware development in the environment of Windows OS and MPLAB X IDE, a highly configurable software program to program microcontrollers and digital signal controllers by Microchip Technology.

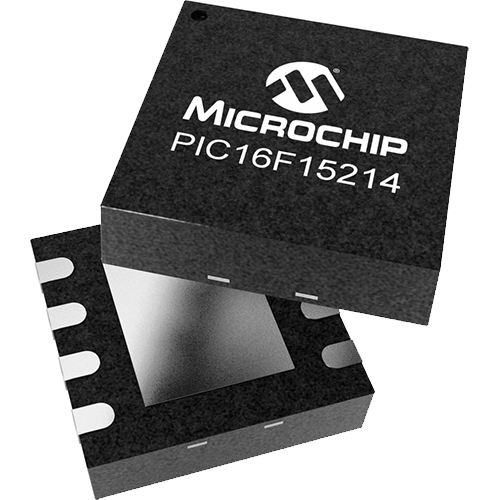

The PIC16F15214 MCU by Microchip Technology powered the device and ensured fast performance in the range of units to tens of milliseconds, meeting the stringent timing requirements of the automotive safety application.

The second high-precision current sensor was designed in compliance with ASIL-C (automotive safety integrity level) to replace the shunt in the battery management system (BMS) while enhancing the accuracy and reliability of current measurements.

Hardware components used in the design of the current sensor:

- Melexis hall-based current sensor equipped with an onboard MCU and digital output over LIN/UART, integrated into the system for precise and digital current measurements.

- Allegro MicroSystems hall-based current sensor utilised for analog output, complementing the Melexis sensor, implemented to provide redundancy and ensure robust current sensing.

- Main MCU (Microchip ATSAMC21) acted as the primary processing unit for data analysis and control, ensured high computational accuracy and efficiency.

- Secondary MCU (Microchip PIC16) served as a redundant MCU for reservation purposes, added an extra layer of reliability to the system.

The system incorporated a CAN communication interface to ensure reliable communication between various components within the BMS.

Our development tools:

- Microchip MPLAB X IDE. Used for developing and programming Microchip MCUs, ensuring efficient code implementation.

- Melexis IDE (eclipse-based). Employed for the configuration and optimisation of Melexis hall-based current sensor parameters.

- TESSY. Used for unit and integration tests, ensuring the reliability and functionality of the developed system.

- Helix QAC. Applied for static code analysis, identifying and addressing potential issues early in the development process.

Business Value

Our client has received two sensors to incorporate into their new product, ensuring compliance with ASIL-C and the ISO 26262 standard for automotive functional safety. With innovative offerings that meet the evolving needs of automotive safety, the company will attract a broader customer base and strengthen its reputation for advanced solutions.